Interpreting Archives Management with Smart Technology

- posted by: hds

- No Comments

In the era of intelligent informatization, which is sweeping in with great force, all industries are adopting smart management. In the age of big data, archives departments are faced with a massive number of files of various types. It is crucial to focus on intelligent management and actively utilize digital technology in the work model. Otherwise, searching for important information in the vast archives can feel like “finding a needle in a haystack.” Therefore, the construction of intelligent archives is particularly important in this fast-paced and highly efficient environment.

Currently, there are several management issues in archival management, such as: archival management largely remains at the level of manual management, with poor confidentiality and high risks. There is a general lack of automatic identification methods, which hinders the development of inventory work; archives generally lack a clear understanding of the inventory information and locations of physical archives, making it difficult to manage effectively; the archival cataloging process is cumbersome and inefficient, and the process of archival retrieval and organization is time-consuming and has a low accuracy rate; the management of expired archives is lagging, with destruction of expired archives not being timely, leading to frequent management chaos due to frequent turnover, and loss or discontinuity often occurs. Some advanced archives have adopted barcode technology for archival management, but barcodes also have some inherent drawbacks that are difficult to overcome, such as being prone to wear, having limited storage space, and needing to be affixed inside books, which brings inconvenience to use and is not entirely suitable for archives.

RFID, which stands for Radio Frequency Identification, is a new automatic identification technology that has revolutionized the management of physical items, following the barcoding technology. Compared to traditional automatic identification methods, RFID technology possesses several distinct advantages, including excellent penetrability, the ability to identify multiple tags from a distance, a large capacity for storing item information, the capability for repeated reading and writing, and the uniqueness of the identification information. These characteristics make RFID exceptionally suitable for the management of physical archives.

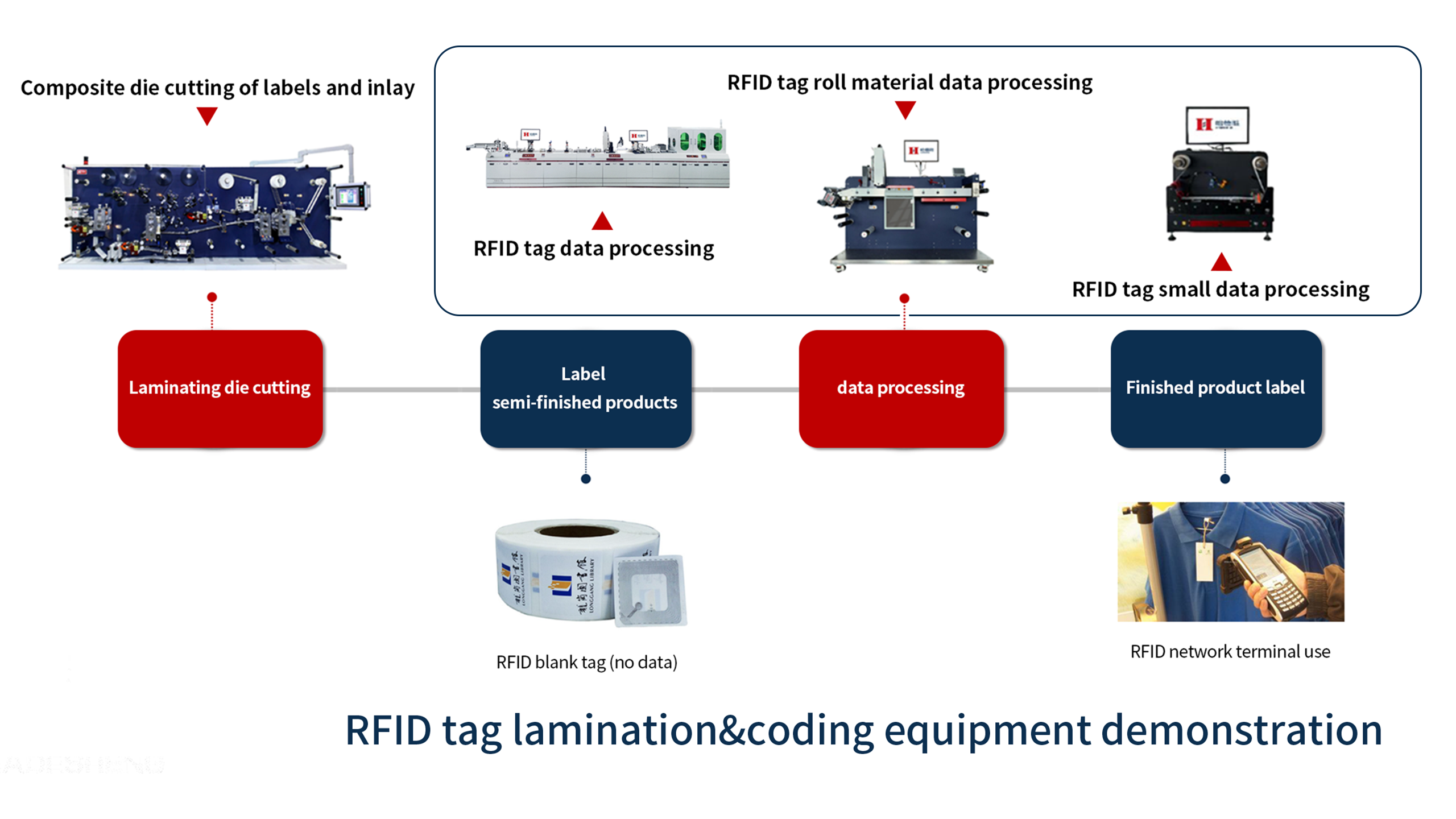

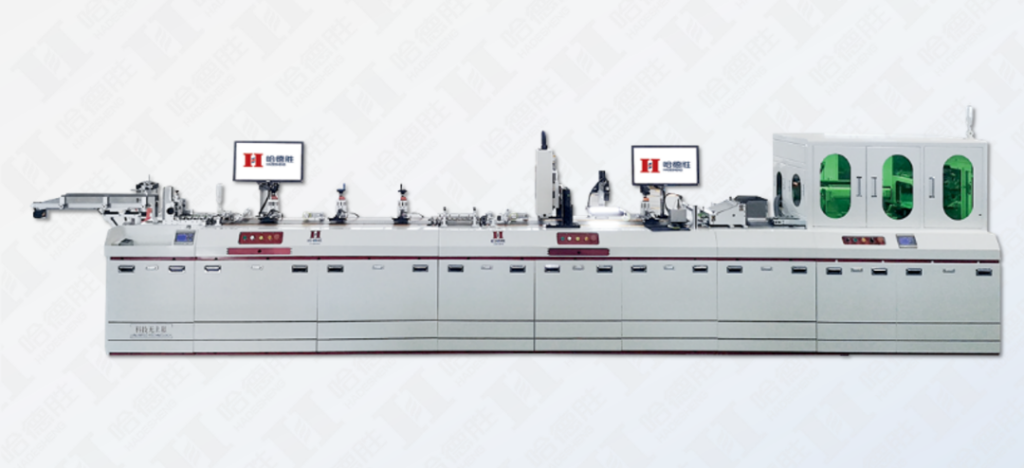

HADESHENG Our independently developed RFID series equipment boasts a range of unique features, including automation, labor cost savings, targeted development, bulk importation, independent coding, large storage capacity, increased production efficiency, and safety protection.

RFID High-Speed Composite Die-Cutting Machine; Die-cutting precision controlled within ±0.2MM; Die-cutting speed of 100 meters per minute; Dry and wet Inlay transfer, dry Inlay cutting pitch of 12mm (industry’s smallest); Satisfies 99% of market mass-produced products with a high yield rate of 99%.

The RFID tag high-speed coding and inkjet inspection machine equipment utilizes a PLC (Programmable Logic Controller) and upper computer combined control method. The PLC is responsible for platform control, while the upper computer manages RFID data detection and writing calculations, UV variable data printing, and CCD appearance inspection, etc. The drive system employs high-precision gear reducers and servo motors, achieving a coding speed of 12 pieces per second with high positioning accuracy and fast operation.

RFID is the core technology of system construction projects, utilizing Radio Frequency Identification technology. RFID technology is the fundamental core technology of the Internet of Things application technology. The principle of this technology involves the RFID transmitter emitting radio waves to activate the oscillation circuit of the RFID tag, generating a current, and subsequently reading and writing the stored information in the chip. This is a new generation of tag identification technology suitable for the 21st century. In terms of technology application, RFID has the advantages of carrying a large amount of information, contactless identification, the ability to read multiple tags simultaneously, and high read-write speeds. It is increasingly recognized by society and is replacing barcode and magnetic stripe technologies. Compared to barcode and magnetic stripe technologies, RFID tags have absolute advantages: rapid scanning, RFID can read multiple RFID tags simultaneously; small size with various shapes; high resistance to pollution and durability; reusability; strong penetration; large memory data capacity; high security: since RFID carries electronic information, its data content can be protected by passwords, making it difficult to forge or alter the content.

After implementing RFID technology, archives management quality has significantly improved in archives even with the same or fewer staff. State Grid, courts, industry and commerce bureaus, talent markets, and other institutions are also in the process of gradually piloting RFID systems. In the future, an increasing number of RFID-enabled intelligent archives will enter the implementation phase.