2022-11-02 15:28:30 Hadesheng View: 711

As we all know, the largest source of oil is in the Middle East. With the continuous expansion of the scale of physical circulation of oil fields, the types and quantities of materials continue to increase, making the supply management of materials more complex and difficult. In recent years, the oilfield material management has been gradually deepened, and the specialized chemical and procedural operation of material supply has promoted the sound operation of the internal supply chain from demand plan submission to material distribution to the production site; The standardized system of oilfield warehousing and distribution is gradually improving; Many oilfield material supply management information systems, RFID electronic tags, GPS and other technologies have been partially applied. The application level of Internet of Things technology in material procurement and supply has been gradually improved, and the basic conditions for realizing the whole process and life cycle management of oilfield materials have been met.

Patrol inspection of oil pipelines refers to the regular patrol and inspection of oil pipelines under the jurisdiction of the oil pipeline management department to ensure the safety of oil transportation and prevent oil leakage. The daily maintenance of oil pipeline is a difficult point in the field of oil pipeline transportation. Patrol inspection is a work with strong timeliness, which requires the personnel on duty to patrol every patrol point periodically.

For a long time, the patrol inspection of oil pipelines has followed the "one table system" to manually fill in the inspection results, which is not only inefficient, easy to miss items or make mistakes, but also time-consuming in terms of inspection time, inspection route and inspection content. Most of the manual inspectors are locally employed workers. It is inevitable that the quality of the inspection work will be greatly reduced due to the differences in personnel and working attitudes.

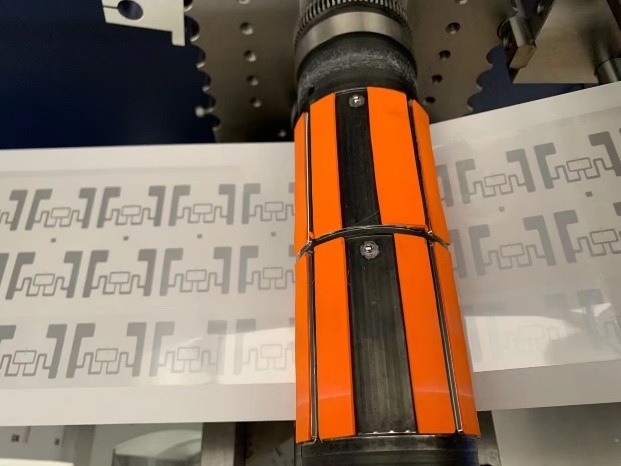

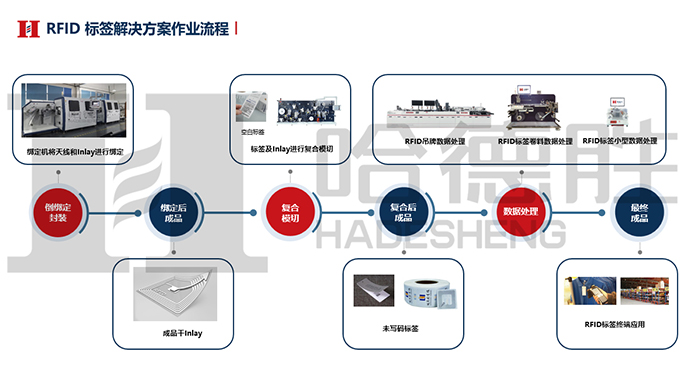

Hadesheng RFID tag high-speed composite die cutting equipment can cut and paste independent four rows of Inlay at the same time, and it is also applicable to multiple materials. The minimum dry Inlay cutting jump distance can reach 12mm. At the same time of standard production, we can also choose to add a variety of defective product detection devices according to different process requirements of products, and realize the identification or elimination function.

Hadesheng RFID tag high-speed composite die-cutting machine is suitable for composite die-cutting of electronic tags. The equipment has a unique overall frame design, which ensures the stability of high-speed production while reserving sufficient expansion space. The stable production speed of three knife sleeve die-cutting can reach 100 meters/minute. At the same time, it is also a highly intelligent design, which can be quickly used by new pilots.

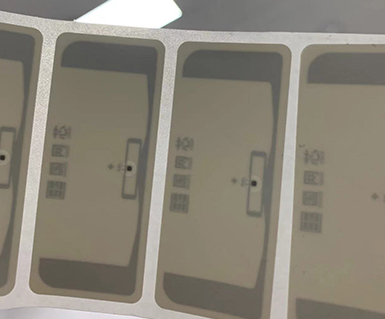

After analyzing the current situation of oil pipeline patrol inspection, the patrol inspection information of wide area or regional oil pipeline and related equipment shall be timely recorded in coordination with the improved background data processing system+RFID electronic tag. Each label has a globally unique mark to prevent forgery and cheating; The special process packaging is adopted, so that the product can adapt to the harsh weather environment of the oil pipeline in the wild; The anti-collision housing can prevent the identification point label from being damaged by external force.

RFID system is interactive, which can timely find anomalies, intelligently set patrol routes, and query personnel, routes, time, patrol status, etc. This intelligent management method can well solve many disadvantages of the original patrol inspection method. According to the patrol inspection information and maintenance information, comprehensive data analysis and processing are carried out, and combined with the patrol inspection feedback information, order issuing and maintenance feedback information are processed. It will effectively reduce the waste and loss of oil, and improve the supervision and management of staff work.