2022-03-28 10:09:23 Hadesheng View: 1686

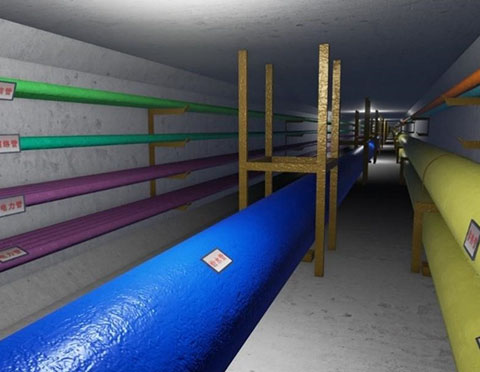

The underground pipeline is the lifeline of the city ,an important channel for the material flow and energy flow of the city,which is closely related to people’s lives.

With the rapid developmetn of social economy ,the underground pipeline system,as an important urban infrastructure,is becoming more and more perfect.It not only brings huge social benefits,but also brings management problems to managers,mainly in two aspects:invisible and difficult to maintain underground pipelines.

Although the underground pipeline is an hidden project ,there are some technical means such as pipeline endoscope to assist the management,but it can only have a basic understanding of the appearance of the underground pipeline,and there and some problems such as inconvenient to use,can not directly obtain the relevant technical data.

At the same time ,the underground pipeline system involves a large number of urban components,and the maintenance of components often adopts the way of manual inspection one by one,which needs to invest a lot of human resources. Therefore,the introduction of RFID tag management means to guide the maintenance and maintenance of underground pipelines,has a very broad application prospects.

At present, most pipe network maps take the ground construction as the reference to locate the pipeline. Because of the accelerated pace of urban construction, the increase of construction demolition, road expansion and transformation and other factors, the change and disappearance of the original reference has a great impact on the quasi-confirmation of the pipeline. Municipal pipe network in water supply, electricity, communication, gas and other raw material pipelines are often congested together, it is often difficult to recognize a certain type of pipeline, put forward higher requirements for daily maintenance and management.

In developed countries, the RFID technology is applied to the management of the CMC and the inspection has been very common, some countries have adopted one CMC installed two labels, which one is installed on the manhole cover, the other one installed in the ground near the manhole covers, ensures the manhole cover loss damage, also can easily find another 1 tag to read the information, Both the UK and Japan now use this approach. In addition, the U.S. has installed video cameras under manhole covers to improve security. Germany, Denmark and other countries use a single electronic tag embedded in the manhole cover to complete daily intelligent inspection work.

In China, some cities have begun to use RFID technology for manhole cover management, such as Shangcheng District of Hangzhou and Haidian District of Beijing. For different requirements and management modes, different technical means can be adopted. For example: through active electronic tag technology, with street fixed RFID reader base station, to achieve automatic alarm function of manhole cover movement and loss, but this way investment is large; Haidian District of Beijing uses electronic tags to complete simple asset inspection and the acquisition of basic information such as the unit.

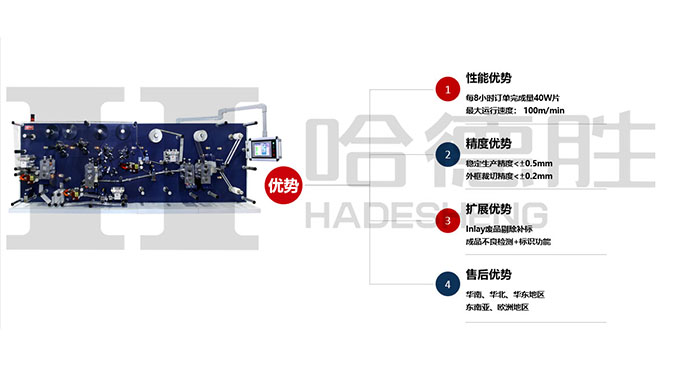

HADESHENG PRECISION COMPANY self-developed RFID series equipment has the unique functions of automation, labor cost saving, directional development, batch import, independent writing code, large storage capacity, production efficiency improvement, safety protection and so on.l high speed RFID label converting &die cutting machine; The precision of die cutting is controlled in ± 0.2mm; Die-cutting speed of 100m/min, dry and wet Inlay transfer, dry Inlay cutting jump distance of 12mm (the industry minimum); Meet 99% of the market mass production of products, high yield rate of 99%

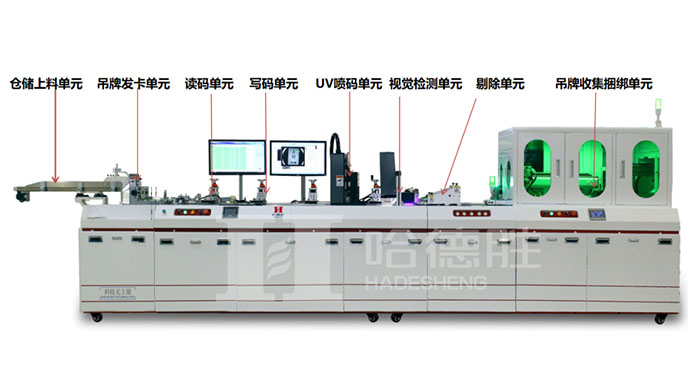

RFID tag high-speed coding & detection machine adopts PLC+ host computer control mode, PLC is responsible for platform control, host computer is responsible for RFID data detection, write calculation, UV variable data printing, CCD appearance detection, etc., driven by high precision reducer + servo motor, write code speed of 12 pieces/second, high positioning accuracy, fast speed.

The application of RFID electronic tag on underground pipeline tube to explore, to effectively solve the underground pipeline information in the process of pipeline maintenance management, the CMC information acquisition, pipe work management, keep staff management difficulties, CMC loss related problems such as slow response, pose a safety hazard, so as to provide convenient underground pipeline pipe work mode, To improve the efficiency of maintenance staff and better serve the public.